Production Capabilities

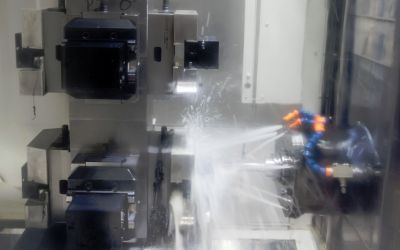

5 Axis Machining

Increased productivity utilizing a reduction in the number of setups required to process a job, therefore increase the quality. CVC places an emphasis on quality and cost. This is reflected in the CVC’s capital expenditures.

Live Tooling

Lathe live tooling on all our lathes removes the need for secondary operations. CVC utilizes C and Y axis on its’ lathes to produce hexagons, slots, and complex features Tooling Management Software – Organization and integration of tooling to ensure readiness and availability. CVC has invested in tool crib attendants, barcoding software, and tool management technology in order to ensure that spindles are running and not waiting on tooling.

Glass Scales

Improved accuracy of CNC machines to achieve tighter tolerances. CVC has invested in accuracy in both long and short term by ensuring its machines are precise as possible.

Probing / Inspection

Automatic offsets and onboard inspection eliminates potential errors. CVC utilizes Renishaw probing to inspect true positions, sizes, and profiles with .0002”.

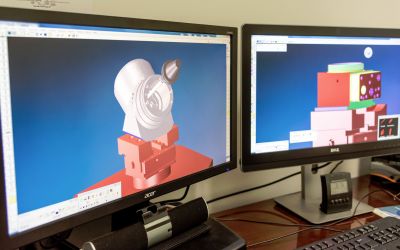

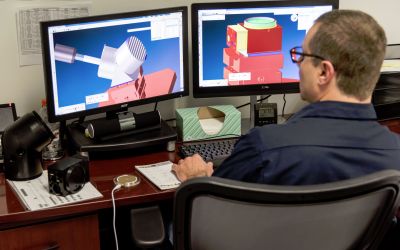

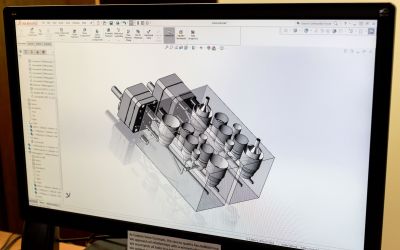

CAD/CAM

Interaction with customer’s 3D model reduces redundancy and error and increases capabilities. CVC uses verified models for simulation, programming, and verification.