Flo-Miser Flow Rate Controller

Specifications

Specifications

> Materials of Construction: 316 Stainless Steel

> Body Seals: PTFE

> Maximum Working Pressure: 1,200 psi (600# ANSI)

> Maximum Working temperature: 400 F

> Process Connections: NPT Female

> Accuracy: ± 5% of setpoint

> Repeatability: ± 1% of setpoint

> Rangeability: 13:1 turndown

> Response Time: Instantaneous

Flo-Miser Size Ranges Available

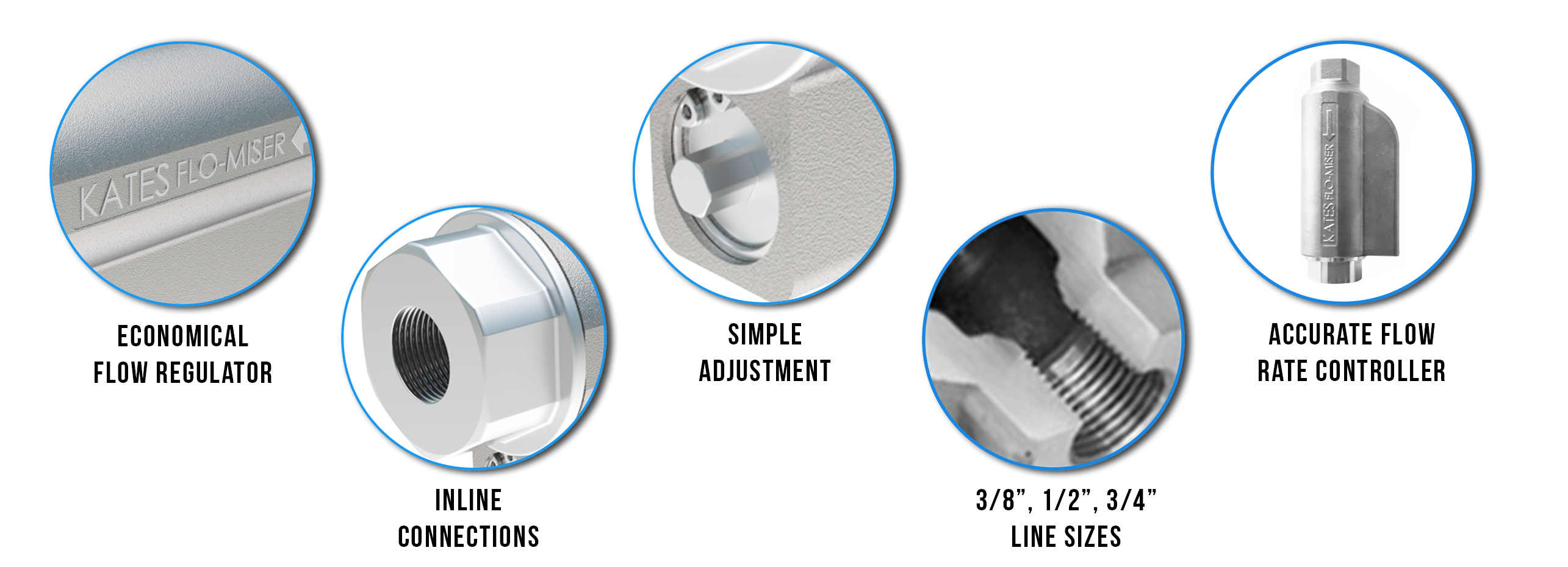

FM38 - 3/8" - 0.3 to 3.0 GPM (1.1 to 11.4 LPM)

FM50 - 1/2" - 1.5 to 20 GPM (5.7 to 75.7 LPM)

FM75 - 3/4" - 1.5 to 20 GPM (5.7 to 75.7 LPM)

Typical Applications

The New Flo-Miser is an economical, lighter duty version of our standard flow rate controllers. It offers much of the same flow characteristics of our high-performance Kates Flow Rate Controllers at a substantially lower cost.

How It Works

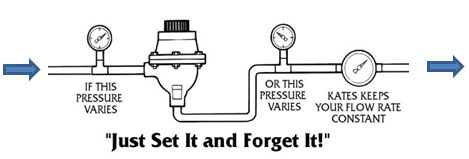

The Flo-Miser combines a characteristic needle valve with an internal differential pressure regulating valve. By controlling the pressure drop across the adjustable orifice, the flow rate will always remain constant. Since the control portion immersed in the fluid is controlling response time to pressure variations is immediate and hunting and oscillation is eliminated.

Easily adjust your flow setpoint by turning the micrometer-like needle valve adjustment. Once set, the Flo-Miser will control your flow accurately, regardless of changes in your process.

Recently, Delta Fluid System did a test with our valve and came away with some stunning conclusions.

"Kates Flow Valve does a great job of regulating flow regardless of downstream pressure variations. Pressure is the critical variable on Plan 54.

When splitting lines on a plan 54, the Kates valve will maintain flow setpoint for each line. In order to maintain equal pressure in both lines downstream the Kates valve, we recommend two independent back pressure control regulators.

When splitting a header the Kates valve will maintain flow, if the return header shares one common back pressure control regulator the lines need to be equal as far as pressure drop goes in order to maintain equal pressure. I can’t tell you how much this has aided in our confidence in the Kates valve.

To be honest, at first, I thought it was smoke and mirrors but now I can eat my words and say “Kates is my preferred way for header distribution flow control."

See for yourself in the video of their testing below.